Our 3 Pillars of Design

Emissions reductions

Safety improvements

enhanced performance

Why Choose an Active System?

Static vortex generators are commonly used by aircraft manufacturers to improve aircraft performance through specific stages of flight. However, since static vortex generators rely on specific boundary layer conditions to function, their range of usability is heavily dependent on numerous factors, including their placement along the chord length of the wing and their height

Check out our USRC Tech-Talk!

Our System Requirements

Easy integration with existing aircraft systems

Due to its reliance on existing technologies and the ability to be easily incorporated into commercial wings with minimal modification, AVIS does not require radical revisions to existing airframe design

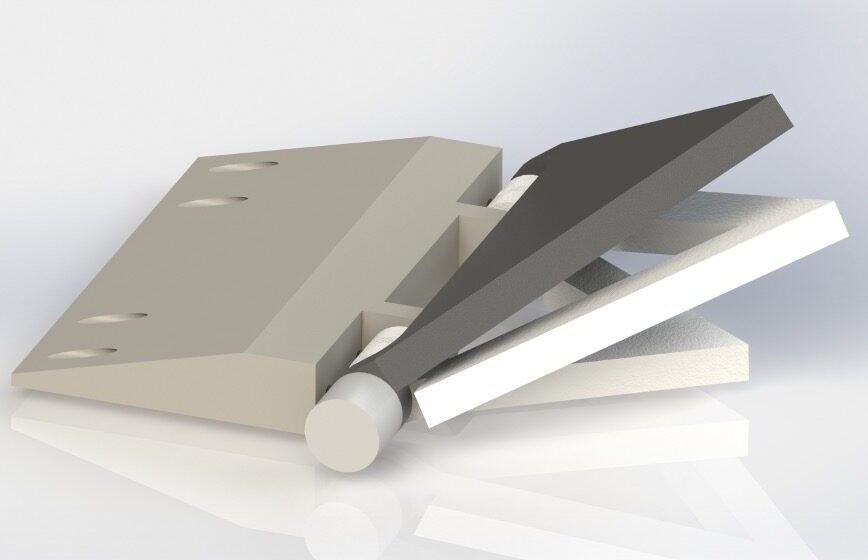

Low mechanical complexity

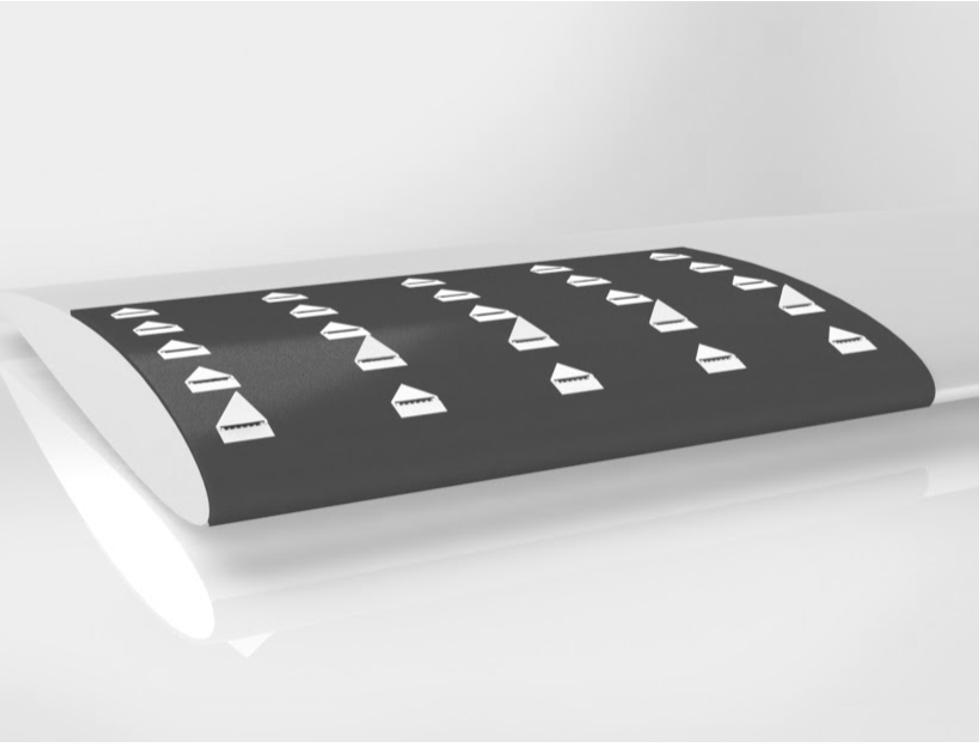

A low-profile design minimally affects the aerodynamic balance of a wing when the system is stored. Furthermore, each Vortex Generating Module (VG) maintains low mechanical complexity, enabling mass production and affording purchasers the benefits of the economics of scale

High frequency actuation

AVIS uses a dynamic array of active vortex generators to achieve optimized functionality across all stages of flight. This allows for the benefits of vortex generators to be seen at all angles of attack while eliminating the drag penalty of static vortex generators

Multi-dimensional actuation

Using existing aircraft data and a transfer function, pre-programmed with the air frame’s specific wing characteristics, AVIS can pinpoint the most effective location for VG actuation at any point along the chord or span within the array